Super Street Truck

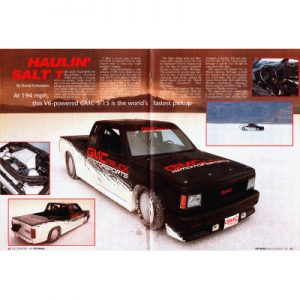

GMC’s SYCLONE LSR trucks into the 200-mph zone

By David Fetherston

Chasing racing dreams can be frustrating – but when everything goes just right, records shatter like glass. As Rick Lee and his crew from GMC Motorsports discovered on Utah”s wide, white salt flats, however, carving out a new standard is not without its drawbacks. The quest becomes an obsession, and the challenge changes. Now the record you ache to break is your own.

In 1989, GMC Motorsport paid their first visit to Bonneville. and succeeded in upping the ante in a big way: they beat out the existing class record by 20mph in the measured mile with a speed of 183.92mph. It was, by all accounts, a rather amazing number for a stock-bodied S-15 Club Coupe pickup.

However, the breaking of that record created yet another challenge. Later in 1989, they went back to the Bonneville salt and slaughtered their own mark with an FIA (Federation Internationale de l’Automobile)-sanctioned speed run – taking the Category A Group II, Class 9 and Category E Group II Class 9 records with a speed of 194.77mph. (The former FIA A-II-9 record holder was a Porsche 928S4).

Not only did that run put the GMC in the record books (again), but it served as a teaser. Lee and his boys had to go back one more time; the possibility of truckin’ through the magic 200-mph zone became their Holy Grail.

The later part of 1990 rolled around and the GMC guys were ready to “cheat the wind” once again. The salt was just perfect, Gale Banks’ Engineering team from Azusa, California, was on hand with Katech’s hot 5- liter V6 pumping out 550 horsepower and Don Stringfellow was suited up once again as the “wheel man.”

The truck is based on 1989’s S-15 racer. However, the S- 15 was freshened up with new sheet metal and the Sonoma Club Coupe aero package.

The new skin concealed a trick Vortex V6 built by Vehicle Research and Development and Katech Inc. from Mount Clemens, Michigan. Based on a 4.3-liter block, Katech opened it up to take advantage of the FIA displacement limit of five liters for the class. Stuffed with 14:1 Diamond Racing pistons, Oliver billet steel rods and a “race only” even firing Moldex crank with common crankpins, the 90-degree V6 displaces 301 cubic inches.

The valvetrain includes steel billet roller camshafts by Competition Cams running Isky lifters and a Katech rev kit. The Brodex alloy heads were fitted with Falconer stainless roller rockers and titanium valves.

Katech wanted plenty of oil on hand, so they set the Vortex up with a super duty dry sump system using a Weaver double pump, circulating oil from a “supply- and-return” tank mounted in the truck bed.

Delivering the Cam II racing gas is a Kinsler fuel injection assembly using a Rochester pump, regulator and injector nozzles. This assembly is housed in a heat-shielded plenum which feeds super cooled air into the injector rams. Bonneville, because of its 4000-foot elevation, often has ultra thin, dry, hot air which is totally unsuitable for racing. To improve the air density. Katech built an intake air system to deliver cooled air through a pair of insulated, large diameter oval ducts to a central plenum.

Before reaching the main plenum chamber, the intake air is cooled by a pair of inline intercooler radiators (converted from Harrison air- conditioning evaporators) mounted just behind the grille in the duct entry.

They are cooled by ice water from a bed-mounted tank which circulates the water at 29 gallons per minute. This system has the same effect as an intercooler on a turbo engine – it reduces the temperature of the incoming air. thus increasing its density which, in turn, helps the engine produce more power with a latter charge. The system has proved perfect for Bonneville’s seven-mile runs as its delivers maximum air density increases during the entire racing cycle and is easily rechargeable with a couple of extra bags of ice.

Dyno figures for the 301-cid engine were quite impressive: 550 horsepower with 429 foot-pounds of torque. However, on race day the engine horsepower was closer to 630.

The engine project is the electronic engine management marvel. Delco Electronics was responsible for the complete capacitive discharge ignition and the engine control module. Delco also developed a complete vehicle/engine monitoring package with sensors to record throttle position, intake air temperature, coolant temperature, crankshaft position, engine speed, vehicle speed, wheel slip, underhood air pressure and air/fuel ratio.

All this data is recorded on board, and then fed by radio telemetry to a base station equipped with a super duty lap top computer system. . . while the truck is racing. This enabled Gale Banks to perfectly tune the truck for all its two-way record attempts.

In packaging the Syclone, the drive system was not forgotten. The five-liter engine uses a triple-disc clutch from Tilton Engineering to deliver its horses to a Weisman five-speed transmission (which features a quick change unit attached to its output shaft). This enabled the team to carefully tune the transmission’s final drive ratio to suit varying conditions and engine dynamics. A lightweight, super strong carbon fiber driveshaft tube was also used, along with a pair of regular production universal joints. The rear axle is a full floating assembly running a set of 3.10 gears.

The front suspension was calibrated to sit on the leading edge of the airdam, about two inches off the salt. This was achieved using the production suspension coupled with Bell Tech dropped spindles. The rear utilized stiffened lowered leaf springs with new upper trailing links to locate the axle and deliver the power firmly.

The 15-inch tire package was the latest technology from BF Goodrich. using a heavily-shaved version of their new Comp T/A R 1 – a DOT-approved street legal radial. The tire is built around a two-ply polyester body, with two steel belts and a nylon outer shell. The GMC mounted 205/50ZRs on the front and 255/60ZRs on the rear, wrapped around Cragar wheels (capped with traditional Bonneville aerodynamic Moon discs for reduced drag).

Inside, the Syclone cockpit has been set up with all the mandatory safety equipment, including a six-point roll cage and an on board fire system. It also featured a Delco Heads-Up display (or HUD) to let driver Stringfellow know his ground speed and percentage of wheel slip.

As you can deduce from this extensive list of preparations. the Syclone had been given some very special developmental attention. The crew from Gale Banks, Delco, GMC Truck and the BF Goodrich engineer were all on hand to perform their perfected trades.

The actual runs were a perfect demonstration of a Bonneville professional team at work. The truck ran down the 12-mile course for a two-way average in each attempt. With a five-mile run up a trip through the measured mile and a six-mile rundown, ‘String” kept the pedal to the metal, pressing past the 200-mph barrier on eight occasions.

His best effort was a one-way average of 210.06mph; the best two-way average turned out to be 204.145mph for the flying mile. These numbers give the Syclone the FIA Category A-Group II Class 9 record for the flying mile and the kilometer.

There was a terrific sigh of relief over the salt encampment when the FIA recorders announced the numbers. GMC trucks were the first to cross the 200-mph barrier, a record that can never be taken from them. A dream had been achieved and the record set straight on who are the “Top Gun” truckers. Sometimes. dreams turn into reality.

Katech opened up the 4.341ter Vortex V6 to take advantage of the five. liter displacement limit for the class. Running a Kinsler fuel injection sys tern Inside the heat.shielded plenum chamber, the mighty mouse was dyno’ed at 550 horsepower – although super tuner Gale Banks had It up above 600 ponies for race day.

At 200mph, the GMC S.1 5 Club Coupe was literally glued to the ground by Its use of readily available ground effects and suspension tricks. Bell Tech components were used up front, along with new upper trailing links out back, to drop the truck to within two inches of the salt.

In order to present the engine with a cool Intake charge, the air was routed through a pair of radiators cooled by ice water pumped out from the bed-mounted tank.

Everything during the record run – from throttle position and intake air temperature to crankshaft position and wheel slip – was monitored electronically by a Delco-devised computer system. It was recorded on board, then fed back to a base station while the truck was still running.

With driver Don Stringfellow leaning on the driver’s side of the GMC, and Gale Banks at the passenger door, the crew is all smiles after the record attempt. The uniquely painted S-15 owns bragging rights as the world’s first 200-mph pickup truck.