Off Road

By David Fetherston

THE VAST FLATNESS OF Bonneville’s chemical wilderness has a strange effect on people. Some stand in awe of its size and loneliness, many admire its rugged beauty, others rub their hands together in anticipation of involvement with the world’s fastest automobiles that race across her barren salt surface. It takes a certain type of driver, carefu1ly prepared vehicle and expert crew to make the “right numbers” happen.

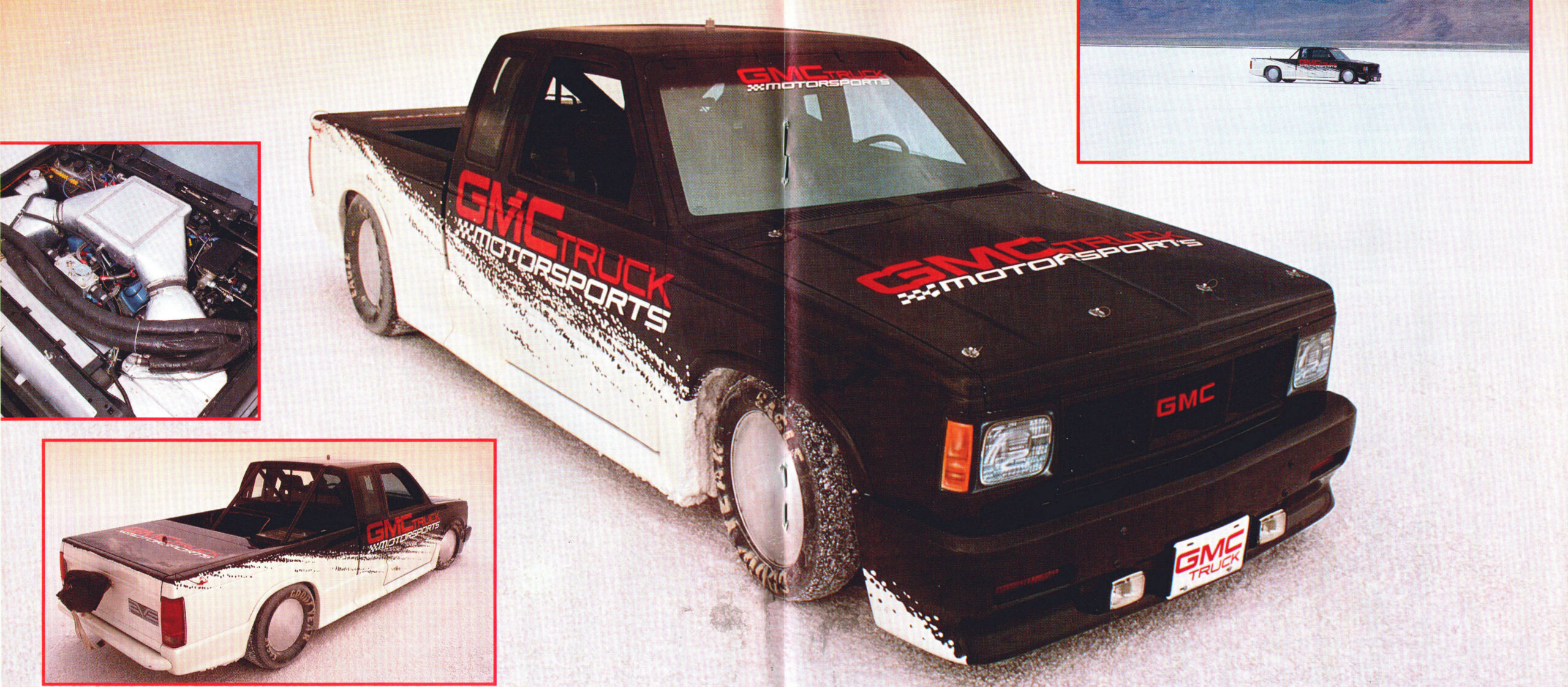

GMC Truck Motorsports, a new division of GMC’s truck division, took a novel approach on the this past July by attempting to breat the FIA Land World Speed Record using a trick 1989 S-15 longbed pickup, the Pegasus III. The venture was an official high-performance project from GMC Truck Design studio and Advanced Vehicle Engineering.

The major design work and fabrication were carried out by the crew at Advanced Vehicle Engineering with the help of Creative Industries Group in Auburn Hills, Michigan. The actual record attempt was overseen by one of Bonneville’s top operators. Gale Banks: behind the wheel Banks placed the “Ozark Mountain Daredevil… Don Stringfellow. Two different engines had been prepared for the attempt. Both are naturally aspirated with fuel injection. For the FIA International attempts, a five-liter V6 was used, and for the SCTA E-Production attempt a special 4.6 V6 will be used later in theyear. AVE joined with Katech Inc in Mount Clemens, Michigan, to build the engines. Bot h use production line heavy duty cast-iron cylinder blocks fitted with trick odd-firing Moldex crankshafts, Diamond Racing pistons and Oliver rods. The heads are Brodix a1uminum.

The upper end of the motor uses a steel billet roller cam from Competition Cams driving Isky lifters and special Falconer stainless roller rockers and titanium valves. The oiling system was also substantially revised with a complete Weaver dry sump system for both engines.

Induction was handled with a perfectly calibrated set of six-throated Kinsler fuel-injection throttle assemblies and manifold hooked electronically into the engine management computer, so it could be accurately calibrated and controlled.

Part of the trick to the truck is the intake air management system. Bonneville is just over 4000 feet up, which, in automotive terms, means thin air.

To help counter the thin air problem, AVE designed an air intake to deliver the densest air possible in the space they had to use. The system uses a pair of Harrison air conditioning radiators mounted in the air intake ducts. The air passes through the radiator’s air passages and on up into a large, insulated fuel injection plenum.

Cooling for these intercooler radiators uses ice water circulated through the radiators by a pair of 1750-gallon-per-hour pumps from a water and ice tank mounted on the floor of the truck’s tray.

The power rating for the 5.0L V6 is impressive: 523 brake horsepower at 6800 rpm along with 414 lb./ft.. of torque.

A Tilton triple-disc clutch assembly was installed to deliver the V6’s massive power to the Weisman five-speed transmission, which has a special quick-change overdrive unit. This helped optimize the gear ratio selection in relation to the engine’s power curve.

Stringfellow already had the S-15 running in fifth gear by the time he entered the end of the second mile, with the timing trap between the third and fourth mile markers.

The rear axle, a special 9-inch full-floating design spun through a unique carbon fiber driveshaft, is suspended on lowered five-leaf springs with a pair of upper trailing links added for better axle torque control.

The front suspension, also production based, uses Bell Tech dropped spindles, which drop the front of the S-15 dramatically. The suspension workover effectively set the 5-15 up with only a slight forward cant. A front air dam was added along with side aero rocker panels to give the truck a surprisingly low 0.31 Cd figure, down from 0.43 Cd for a stock S-15.

The Club Coupe S-15 Interior features a full six-point rollcage along with all the other mandatory safety items. Interestingly, Delco has built a special H.U.D. (Heads p Display) for the truck. It functioned but in the dramatically contrasting light of the salt flats it was difficult to read.

One of the purposes of this venture was to meter all the functions of the vehicle. The S-15 was covered with dozens of tiny sensors that constantly measured the system status for transmission back to the base station on the side of the track, via an on-board computer and a radio link. This allowed the crew from Motorsports constantly to monitor and record all the truck’s functions, from wheel slippage and underhood air pressure to individual exhaust header temperatures, in the comfort of a specially prepared motorhome.

The outcome of all their good work put them on the Bonneville salt, ready to run. The attempt was to break the FIA Category A, Group II, Class 9 record for the Flying Mile and Flying Kilometer. The 171-mph record was set by the late Al Holbert in a Porsche 928 S4 on the salt flats back in 1986.

According to Rick Lee, Director of Marketing for GMC Trucks, “It was surprising to us that the truck was raced against a Porsche record but under the HA classification system, It was the record to beat for the type of vehicle we were using.”

Running on near-perfect salt, Stringfellow scorched through the traps with a new 183-mph two-way average record. The crew immediately turned the truck around and Stringfellow went out and smashed the new record he had set only a few hours before with a 192.545- mph record.

The next day Stringfellow rolled out once again to see just how far he could press the “speed envelope.” His final two-way run resulted in an average speed of 194.770 mph. Those numbers smashed the old Porsche record by more than 20 mph.

It was the first time on the salt for the GMC Truck Design Studio and the AVE guys from Detroit. Without the expert help of Katech, Gale Banks and Creative Industries, the Pegasus III project S-15 Club Coupe would still be a paper dream.

The Club Coupe S-15 allowed a larger interior for computer and video monitoring equipment. Dozens of sensors on the truck were patched into a live radio link so the truck could be monitored on the fly.

Not your normal fuel injection, a special set of six-throated Kinsler fuel injection throttle assemblies and manifold went on the 5.0-liter V6.