Motor Trend

Membership in the Four-Second Club is prized beyond reason and exclusive beyond belief. There are probably fewer than 10 production cars that are members. Qualifying is simple: Accelerate from rest to a calibrated 60 mph in than 5.0 seconds. We know, you’re thinking that’s no big deal, Top Fuel dragsters go 300 mph in that same time.

Yes, they do, with somewhere. around 5000 horsepower and tires made of Super Glue. For this discussion, we talking production cars—cars manufactured in relatively large quantities—which must satisfy EPA, DOT, CAFE, your insurance company, and, significantly, with street tires. To see how difficult it is to get a production car to mph in under 5.0 seconds, let’s look at some numbers.

To accelerate a 3000-pound rear-drive car to 60 mph in seconds requires a force of 1650 pounds be exerted on the car for the full 5 seconds. This force must come from the tires. If the car, has a 50/50 weight distribution, each rear tire is supporting 750 pounds of static weight. When the accelerates, weight transfers to the rear (for this example, 100 pounds per wheel would transfer), bringing the total vertical load on each rear wheel up to 850 pounds. Assuming a friction coefficient between tire and surface of 0.9 allows each tire to generate 765 pounds of thrust. The total from both tires of 1530 pounds is short – of the needed 1650. If the engine can supply more, it’ll end up as wheelspin.

These numbers are approximate, but illustrate the point. Regardless of how much torque the engine can send back to the rear axle, the vehicle described will not be able to make it to 60 in 5 seconds. It weighs too much and doesn’t have enough tire. So, rules No. 1 and 2 for membership in the FSC are low weight and big, sticky tires.

Notice in the above discussion how the thrust to accelerate the vehicle is highly dependent on the weight on the rear axle and the amount of dynamic weight transfer during acceleration. This favors cars with a rear weight bias and short wheelbase (better weight transfer), like the Porsche 911 Turbo at 4.9 seconds. Rule No. 3: As important as how much total weight is that as much weight as possible is over the drive wheels.

However it’s not necessary to have — the engine behind the rear axle like Porsche to get this extreme rear weight bias. Mid-engine cars can have rear weight bias, like club members Lotus Esprit X-180R at 4.7 .seconds and Ferrari F-40, on record with various sources at 3.9 (questionable production status, but a good example of a lightweight vehicle).

At this point, you -may be wondering why we haven’t mentioned front-drive vehicles. It’s because they’re terribly handicapped in hard acceleration by weight transferring off the drive wheels. It’s a classic Catch-22; the more thrust they generate, the more weight they transfer off the drive wheels. We don’t know of a single front-drive production car that’s a club member, and we’ve tested all of them. Rule No. 4 is simple: no front-wheel drive.

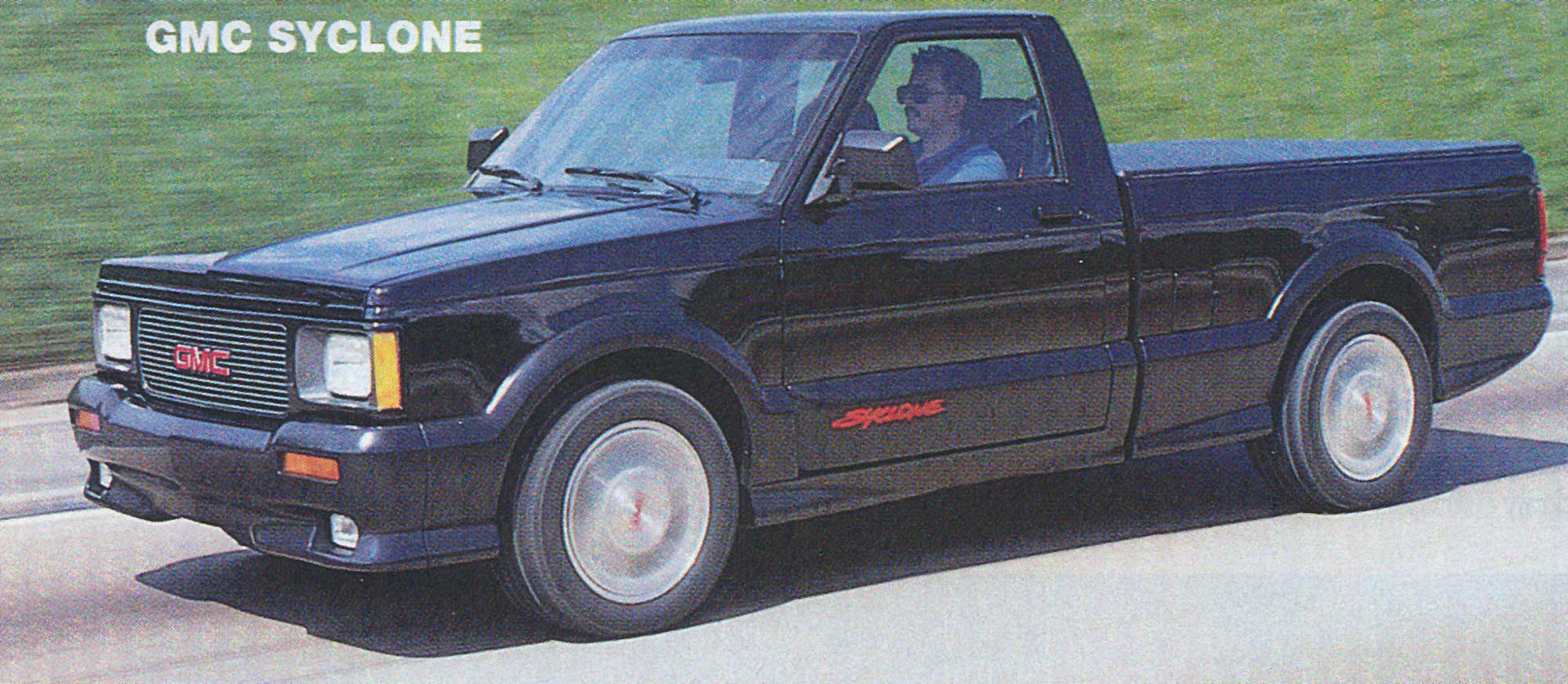

A special category is four- or all-wheel drive. For 0-60 performance, the more tires developing thrust the better, and the GMC Syclone is a good example, a pickup truck that gets to 60 in 4.9 seconds. The Porsche 959 (another questionable production car, and one no longer being built, at that), at 3.9 seconds, is probably the world’s fastest four-wheel-drive car. Its real-world descendant, the Carrera 4, has been clocked at 4.8 seconds, so it’s another member of this elite and fleet group. Front-engine vehicles usually have front weight bias, but in some high-performance cases, weight distribution can be 50/50 or even rear biased. Case in point is the most recent Corvette ZR-1 we tested, a FSC member at 4.9 seconds. The newest FSC member and subject of the attached comparo is Chrysler Corporation’s Dodge Viper.

Its 4.8-second 0-60 time establishes it as a member in good standing. The Viper’s weight distribution is exactly 50/50, but the most significant contributor to its 0-60 performance are the unbelievable 335/35ZR17 Michelin tires on the rear—the ultimate high-performance, street tire on what’s perhaps the ultimate American factory hot-rod.

For 0-60 performance, traction has proven more elusive than power. High horsepower is something easily developed in the comfort of a dyno room. But the intricate interaction of powertrain, chassis, and tire is something far more mysterious and far less repeatable. And the design requirements for coming hard off the starting blocks work at odds with those of cornering capability and stability. As with all things automotive, it’s a complex network of compromises, and only in a handful of cases do the engineers of the world have the opportunity, and resources, to gain admission to the four-second club.