Truck & Sport Utility Performance

Start with one of America’s most popular sport utility vehicles, ad a 280 horsepower turbocharged engine and full-time four-wheel drive and you have a Typhoon. Include a list of aftermarket products with up to 150 more readily available horsepower and the storm gets intense.

by: Gregory Von Dare

Several years ago, on the barren, crystalline plain of the Bonneville Salt Flats, history was made in the blustery winds of an approaching thunderstorm. From far in the distance, a tiny speck grew with remarkable speed, turned into a black compact pickup truck that roared through the timing lights, then vanished over the horizon.

The little turbo V-6 truck had just demolished a world speed record at 197 mph. Only the quickening storm prevented GMC Truck’s engineers from entering the famous 200 MPH Club.

That same pickup came back to Bonneville the next year and went as fast as 210 mph. It had been aptly named the Syclone LSR. To capitalize on this historic event, GMC created a street-going version of the record breaking pickup, also dubbed Syclone.

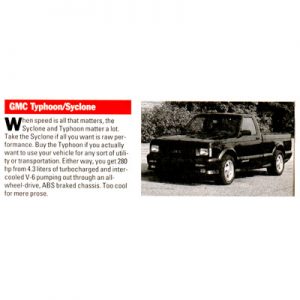

While the Syclone turned enthusiasts minds to jelly with its performance and garnered some of the most positive ink in recent auto journalism history, sales of the $25,000 pickups were unfortunately slow. GMC’s engineers and marketers put on their thinking caps and began planning for a modified s port/utility companion vehicle, based on the popular Jimmy. It would be called the TYPHOON.

“Response to the Syclone was very positive,” said Mike Kramer, platform manage r for the Syclone and Typhoon at GMC Truck. ”But, very honestly, there’s more utilitarian value in a Jimmy because it carries more people. It’s got a broader market spectrum.”

GMC scheduled the Typhoon for limited production in 1992 and ’93. Only 5000 vehicles will be built in all, giving them added collectible value in years to come. “For a GMC Truck to do something like this is c lose to outrageous,” Kramer added, “but it sets the stage for new types of customers and t hat’s really the issue here. We’re trying to attract people who like fun-to-drive vehicles.”

The Typhoon is 4 inches lower than the standard Jimmy. Special aerodynamic moldings begin at the front bumper and wrap themselves back over the wheel wells and rocker panels, creating the “ground effects” look of an exotic sports car.

Beneath that slippery exterior, the Jimmy suspension (with A-arms in front and a live axle rear) has been extensively modified, with racing-type shock absorbers and a pneumatic, auto-leveling back end. The rear suspension was re tuned for better handling in 1993 models. A heavy-duty, four-speed automatic transmission is standard, as are four-wheel anti-lock brakes.

Performance springs from GM’s 4.3 liter Vortech V-6. The s tock engine is tweaked , turbocharged, intercooled and given port fuel injection. All of which persuades it to produce 280 brutal horsepower and 360 ft./lbs. of torque. That plethora of power is fed to the ground via fulltime four-wheel drive, through cast alloy wheels and 245/50VR16 tires. Very racy, indeed.

Inside, there are leather covered seats and door panels, a very functional instrument cluster, with round gauges, including a “wow” meter to tell you when the turbo is cooking. Other amenities include a leather-wrapped steering wheel and one of the best stereo CD players we’ve ever encountered along with an outstanding sound system. Sadly, there was no sunroof.

The nice thing about the Typhoon is that, despite the rocketsled acceleration, the driver still feels very much in control. There is excellent power steering to take you through the corners and capable power brakes. Although, our personal wish list for this vehicle would include four-wheel disc brakes, perhaps from a Corvette, rather than the stock front/disc rear/drum combination.

At partial throttle, the fourspeed overdrive automatic shifts with something of a kick. But at full throttle the sturdy robo-shifter slips up to the next gear with amazing smoothness and speed.

The Typhoon begins life as a standard GMC Jimmy, then is delivered to the PAS company where the turbocharger and other engine and chassis modifications are performed. Then it’s returned to the Pontiac, Michigan plant where GMC adds final trim and performs quality control on the vehicle.

Beyond the Stock Typhoon

While the s tock Typhoon delivers an outstanding level of performance, there are always farther horizons to explore. We’ve found the leading Typhoon tuners in the USA and discovered their performance secrets. First on the list is increased turbo boost.

When our company first reviewed the new Typhoon (Turbo Nov. ’91) and a variety of Syclone/Typhoon performance modifications (Turbo Jan. ’92), we issued some dire warnings about using higher than stock boost pressures without adequate fuel management.

These warnings still hold true but, this past year, many of the companies that modify the Syclone/Typhoon have been hard at work. At present, we can all relax to some degree. There are now quite a few Typhoons around the country running up to 17psi boost, with proper fuel management.

The vehicle featured on the cover of this issue was prepared by Mech tech Motors ports in Escondido, CA using a variety of aftermarket components, with excellent results. Over the past few years we have worked with Mechtech on several projects involving forced induction on everything from dune buggies to large trucks and found them to be a quality conscious shop.

Heeding our warnings on boost levels for the Typhoon, Mechtech owner Jim Mc Farland proceeded in three careful stages, finally reaching what he felt was the ultimate street package.

Stage I consisted of an added HKS Electronic Valve Controller, which will let you run three preset boost pressures at the touch of a button; or, by depressing the manual button, dial-in your own. This unit will also let you reduce boost pressure when towing or using a lower grade fuel in an emergency.

An Applied Technologies & Research performance chip was utilized to control the larger 45 lb./hr. Lucas fuel injectors. To keep the charge air from the turbo at its coolest, there is a Conley’s Performance Plus air/water intercooler. This larger intercooler should be one of the first items on any Typhoon performance shopping list, along with a can of Red Line “Water-Wetter.”

For those of you not familiar with the “Water-Wetter,” it is an additive that breaks down the surface tension of the water allowing more rapid heat transfer between the metal and the water, and vice-versa.

We have used this fluid successfully in the radiators of tow vehicles and 1000+ horsepower Bonneville cars, and it works. Temperature drops between 10 and 30 degrees have been noted depending on several variables. As an additive for an air/water intercooler, it allows about a 10 degree drop, making it a very worthwhile tool, particularly for a vehicle like this that will be spending most of its time in the Nevada desert.

For improved air flow into the turbo, a large K&N air filter was added. Rounding out Stage I was a Borla high flow muffler combined with a custom exhaust system fabricated by Mechtech.

Stage I took the 0-60 times from the low six-second, best of 6.05, in stock trim down to the mid-fives, with a best of 5.43. Maximum boost pressure in Stage I was 15psi.

After a few months of driving, it was time for Stage II which consisted of a larger (Mitsubishi TDOSH) high flow turbo, Kenne Bell billet fuel pressure regulator and an Art Carr 10-inch non-lock up converter and valve body reprogramming kit.

The converter helps when moving up to a larger turbo. The larger turbo will provide greater air flow and maximum horsepower, and the higher stall torque converter lets you build a few pounds of boost pressure before launching. Proof of the effectiveness of this system were 0- 60 times in the low fives, with a best of 4.98, and quarter mile times around the 13.50s. Maximum boost pressure in Stage II was 15psi.

For more serious and adventuresome enthusiasts, there is always another stage or two. In this case Stage III consisted of some mild porting work on the heads and installing larger 1.6 exhaust valve. Some major performance gains were attributed to a Crane street-legal camshaft (P.N.18411), 1.6 roller rocker and high performance valve springs.

It seems that the factory utilized fairly weak valve springs, both for less rolling resistance (fuel mileage) and as a built-in rev-limiter. With the Stage III components in place, 0-60 times dropped down to the high three second range with a best of 3.68 and quarter mile times of 12.19@ 115.2 miles per hour.

In driving the Stage III package there were two items of importance: First, it moved out briskly as the numbers indicated; but just as important, we co1,1ld see no meaningful loss in driveability. Idle quality was good, although you could tell the cam .was there, and part throttle operation was as good as showroom.

The owner of the vehicle, who lives in Las Vegas, reported slightly over 20mpg on his maiden voyage home with the Stage III system, and after a few weeks of operation at 17psi, no mechanical problems.

Anything past Stage III .and 17psi boost would require forged pistons, perhaps JE pistons which give less noise than any of the heavy-duty forgings due to a hightech skirt design.

Overall, the Typhoon is an extraordinary machine, an instant collectible and a guaranteed winner in the stoplight Grand Prix. Our relatively simple modifications have brought it to a performance level usually enjoyed by foreign exotic cars like Ferraris and Lamborghinis, without any loss of driving pleasure or reliability.

Won’t the guy in the ZR-1 Corvette have a stroke when your Typhoon passes him like he’s standing still?